SEPTEMBER 26, 2023

Biogen Implementation of a Reusable Rental Parcel Thermal Shipper: Masterclass Highlights

At a recent industry conference, Sonoco ThermoSafe and Biogen presented a Masterclass session with pharmaceutical shippers and logistics providers. With sustainability on top of agendas for most pharma companies, considering more sustainable packaging is a key pillar of that strategy. With that comes the sometimes-complex evaluation of the different packaging technology and service models – how do you choose?

This article focuses on how one company traversed the landscape of the many packaging technologies available, outlining key considerations in the business case, and the specifics of implementing a new technology and partnership.

Goals

Biogen was looking for a Next Generation shipper that maintained the same payload dimensions. The project objectives included:

- Replacing existing packaging with higher performance packaging

- Reducing packaging weight and dimensions and associated logistics costs

- Adhering to sustainability targets

- Integrating new packaging with existing 3PL partner

Packaging and logistics costs

The masterclass discussed the stark comparison between single use shippers vs. rental packaging in relation to cost. Can cost per SKU be calculated? The answer is yes, based on weight and volume.

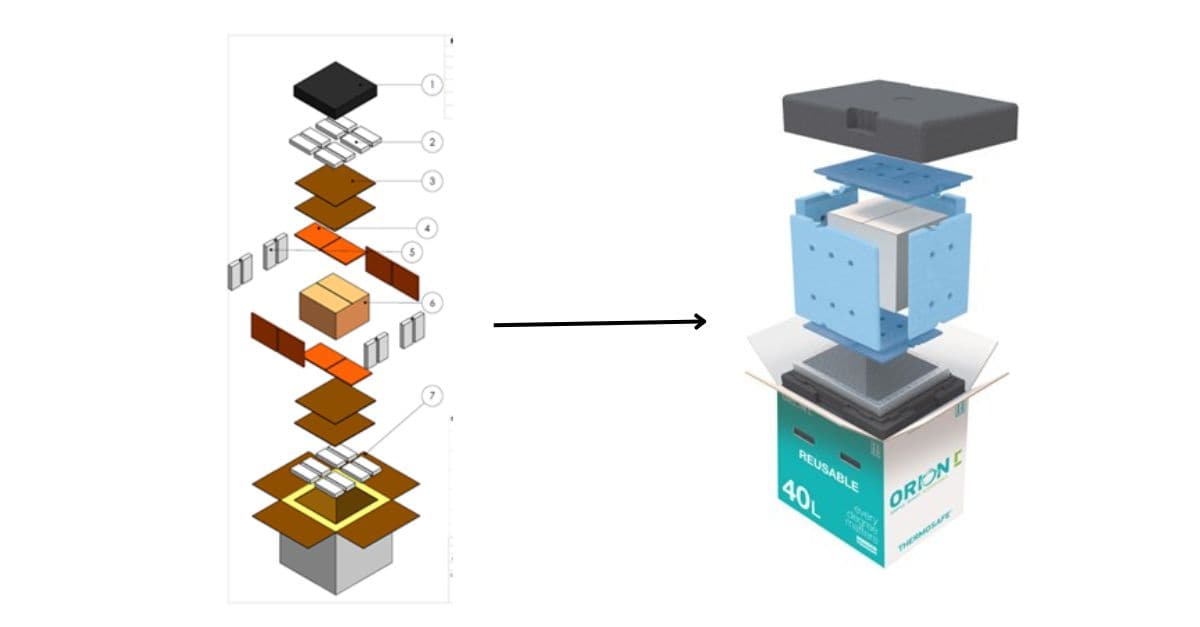

The Orion reusable shipper’s outer dimensions are lower than the previous shipper due to several cost-saving compounding factors. The Orion uses only 6 cooling components, or bottles. Whereas the previous shipper had 12 components. This led to approximately 50% less total system weight (and less cost). In turn, this meant the Orions could be stacked on a pallet for shipping and storage, reducing overall footprint and space – again resulting in cost-savings.

When considering new packaging, it’s worth evaluating different packaging configurations such as VIP + PCM to help achieve your packaging objectives which can in turn drive logistics savings.

Operational handling comparison

One of the major differences in reusable rental packaging is the service needed from program partners. The 3PL plays a significant role in successfully managing the use of rental packaging and their support and integration is crucial to the program functioning. The goal for Biogen moving to the Next Generation shipper was to realize minimal impact to receiving and managing inventory.

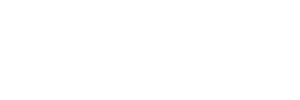

The packout of a thermal packaging system can play a significant role with reducing complexity, in terms of variable overhead cost at a 3PL facility. A goal of the Biogen reusable shipper program was to ensure operational improvements were realized by the 3PL. A key part of this was moving from 4 minute packout time with the previous single-use shipper, to 2 minutes with Next Gen reusable shipper. This is in part due to 14 less refrigerant parts needed to be used during the packout process, realizing a 50% reduction in handling time.

The complexity of kitting and shipping a box was significantly reduced and the 3PL partner benefited from only having to remove a lid and single refrigerant bottle to load the Next Gen Shipper with Biogen’s product and return the components to close the box. The Next Gen Shipper also uses geometrically unique, single refrigerant temperature range phase change material (PCM) bottles, removing any human error concerns with incorrectly assembling or returning components to their proper position.

Sustainability targets

Aligning internally within a pharma company is important to progress sustainability initiatives, but also it’s also critical in working with a rental packaging partner. For Biogen, finding a vendor that prioritizes sustainability in their organization and also be able to provide sustainability reports was key decision criteria.

As an organization, Sonoco ThermoSafe is leading the way in thermal packaging sustainability, considering sustainability impacts for the complete lifecycle of our packaging, from sourcing of materials, to manufacture to end of life. Learn more how exactly Sonoco ThermoSafe reduces Scope 1, 2, 3 emissions across our operations and business.

Sonoco has been actively involved in customer sustainability projects for many years. Each year, Sonoco is awarded the Gold Ecovadis rating, as well as other notable Sustainability accolades, consistently year after year. Most recently, been named as USA Today’s list of America’s Climate Leaders 2023. Learn more about how Sonoco’s reports annually into multiple standard setting bodies and indexes that prove Sonoco’s actions and commitments to sustainability.

Summary of Outcomes

The Biogen team has set up and realized many of the original expected outcomes and will refine expectations as more lessons are learned with ongoing shipments. Outcomes so far include:

- Maintained existing payload dimensions

- Simplified the pack-out and reduced labor

- Reduced the outer dimensions

- Achieved a total transportation cost savings

- Successfully integrated with existing 3PL partner

- Reported sustainability targets

The 3PL partner also realized the complete list of their operational benefits with the transition from preparing and handling single-use shippers to the Next Gen Shipper. The immediate benefits were lower preparation and assembly time, and the elimination of human error driven events, such as incorrectly configured shippers.

Where will you start?

Moving from an ownership to rental packaging model is a large undertaking. That’s why fully evaluating various rental models, according to your supply chain lanes and products is imperative to the success of a program. In addition to a number of other factors.

Top 10 areas to consider when considering rental thermal packaging:

- Models (Rental, Lease)

- Network (Locations, service radius)

- Order Process (Self-Service portal, lead times)

- Fleet Management (Asset pool size, network and availability)

- Quality Preparation (Infrastructure, processes)

- Technology IT Integration, shipment visibility)

- Returns Management (Technology supported processes, partners)

- Rate of Return (Receiving site dynamic, loss rate allowances)

- Refurbishment (Reuse, program coverage)

- Information (Data, intelligence)

Reach out to Sonoco ThermoSafe to learn more about how rental packaging works and discover the Orion reusable rental thermal packaging program.

Contact the Orion Product Manager, at Andrew.Heholt@sonoco.com.

Or if you want to keep learning and curious if your operations and organization are ready for sustainable rental packaging? Use the “Checklist: Are You Ready For Reusable Rental Packaging?”